The SRAM Automatix two-speed gear hub

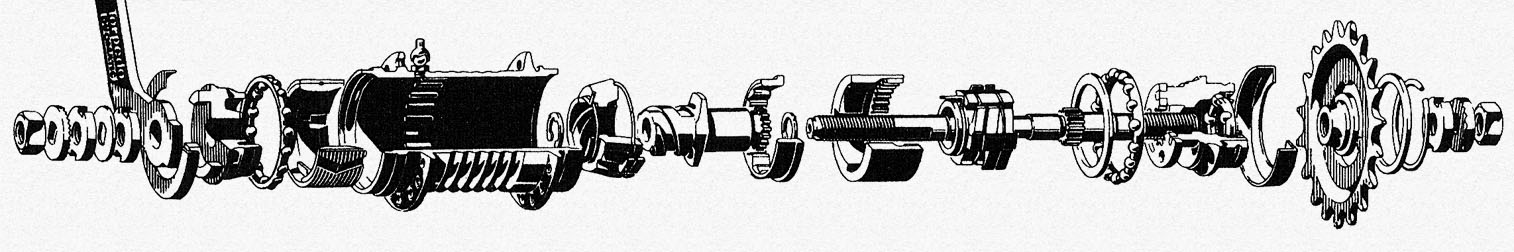

The SRAM Automatix internal gear hub with centrifugal clutch automatic shifting was produced from 2011 to 2017 as the spiritual and also technical successor to the seventies and eighties' Sachs Torpedo Automatic model A2110.

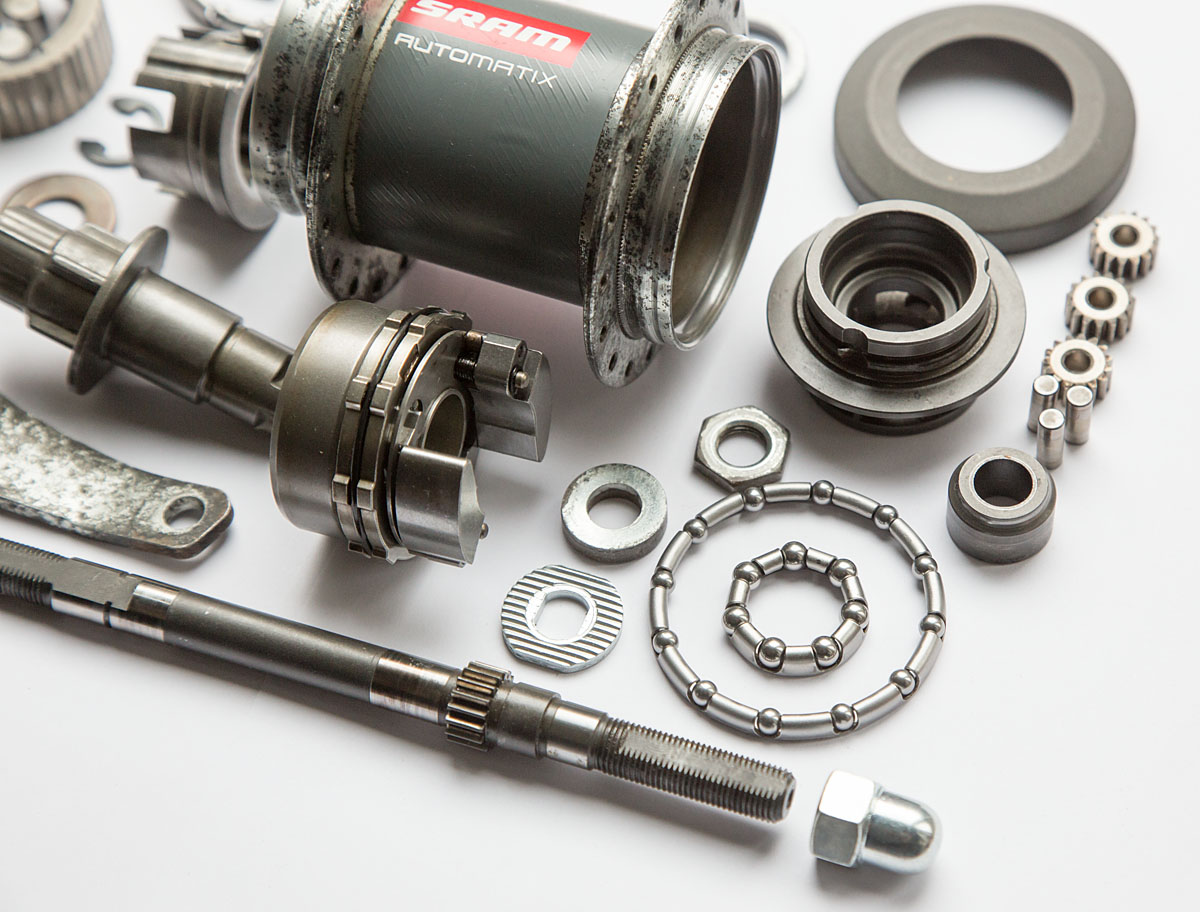

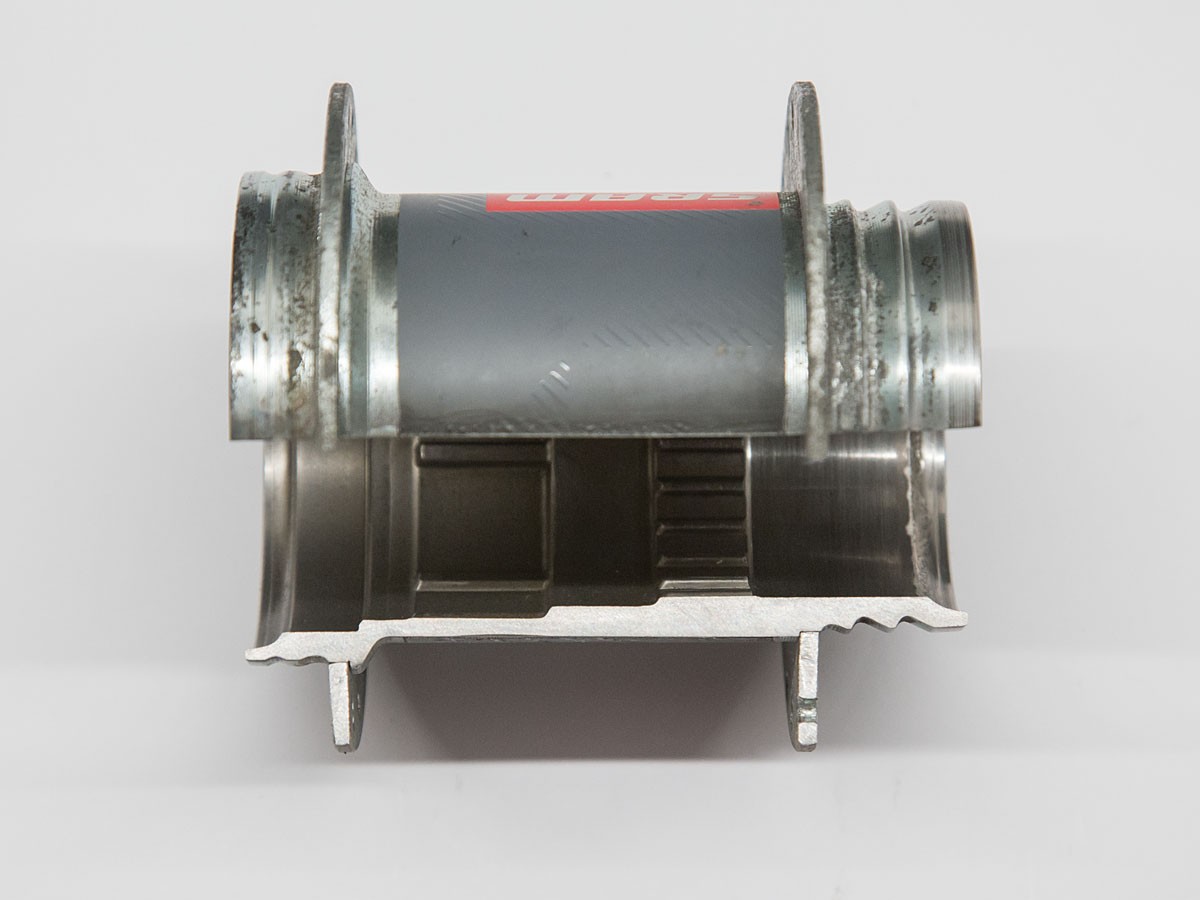

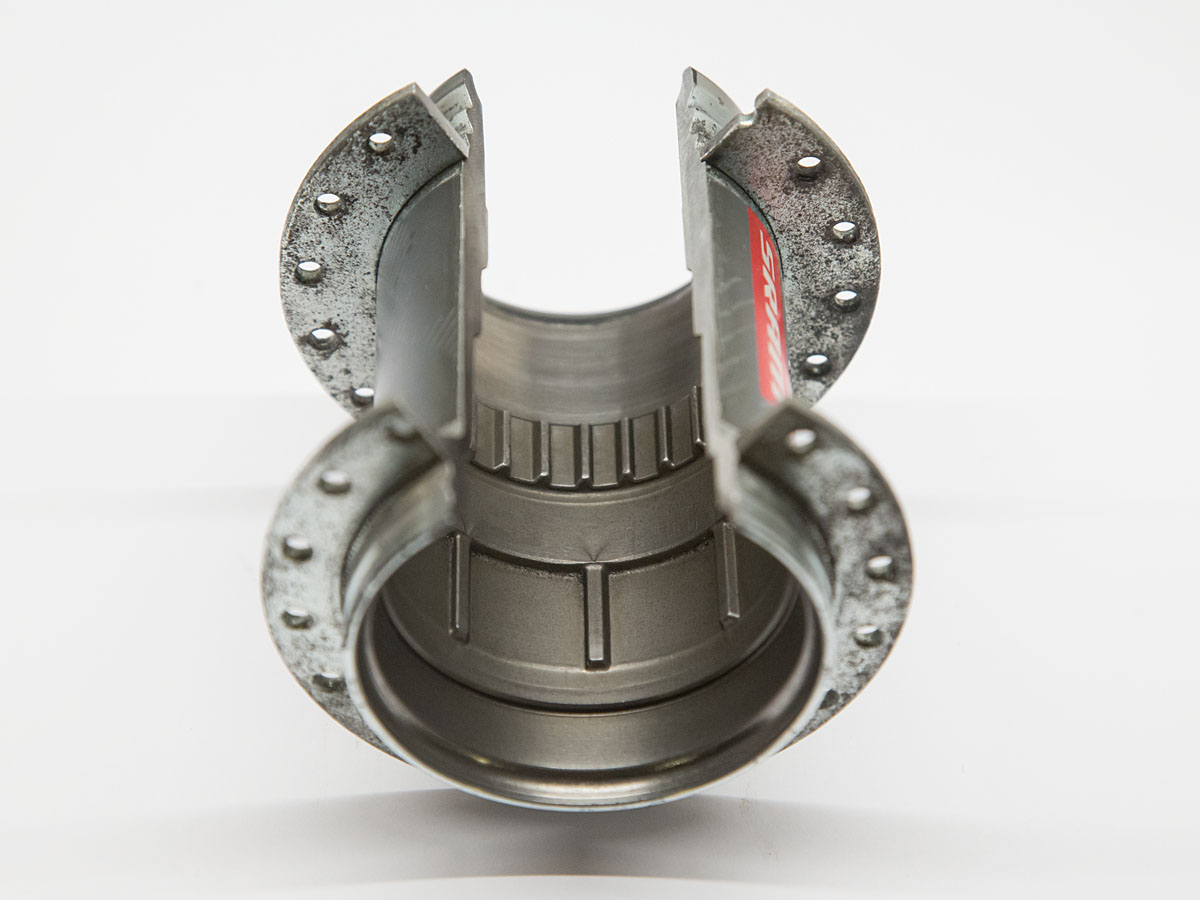

The hub disassembled (centrifugal clutch sub-assembly kept together):

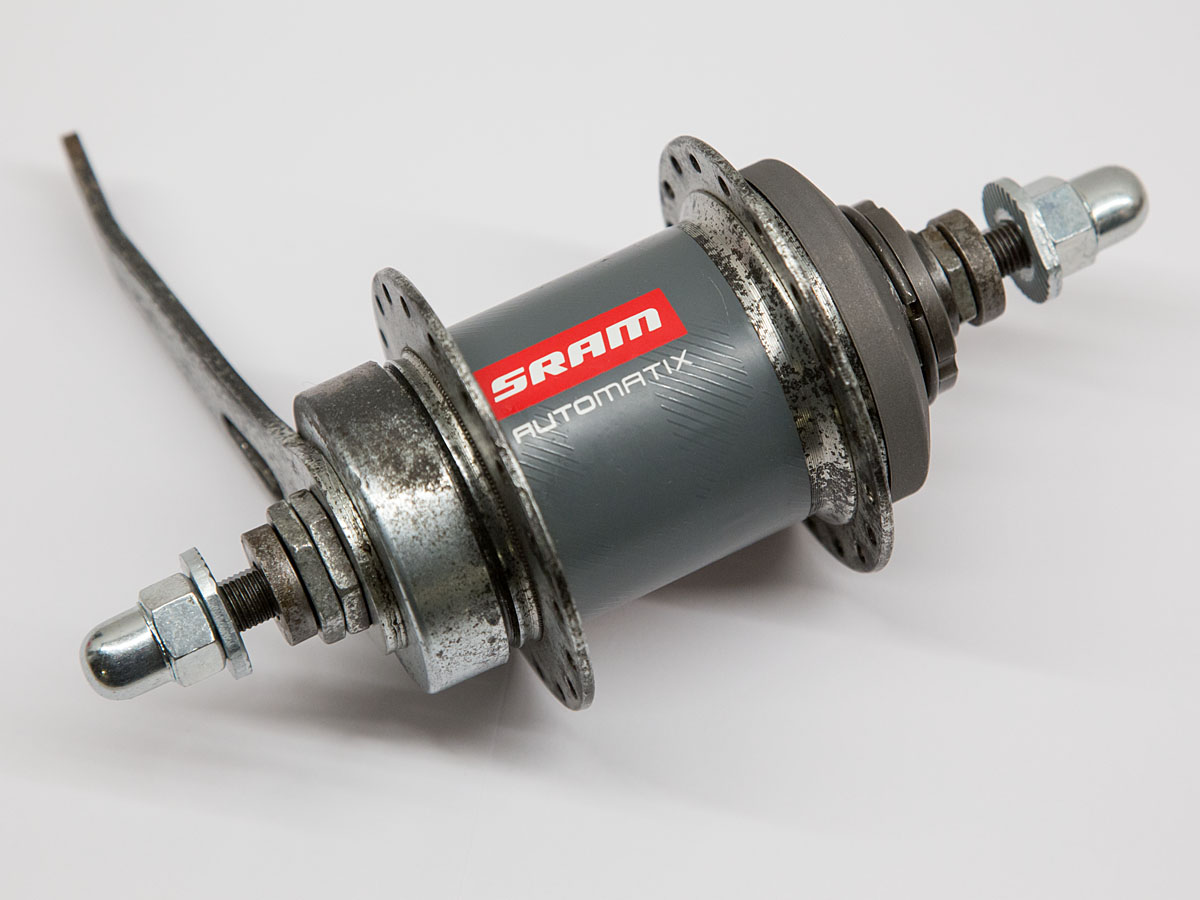

There are also brakeless versions of the hub.

The type and thickness of the hub shell surface galvanization used on the steel versions of the Automatix hubs is unfortunately not great compared to the older Duomatics, so they will get visually/cosmetically tarnished on the outside as shown on the photos if used in Scandinavian winter weather. But the internal mechanism is well designed and sturdily constructed.

Cross section cut-away showing the construction of the hub shell and the mandrel forged internal profile and pressed-on hub flanges:

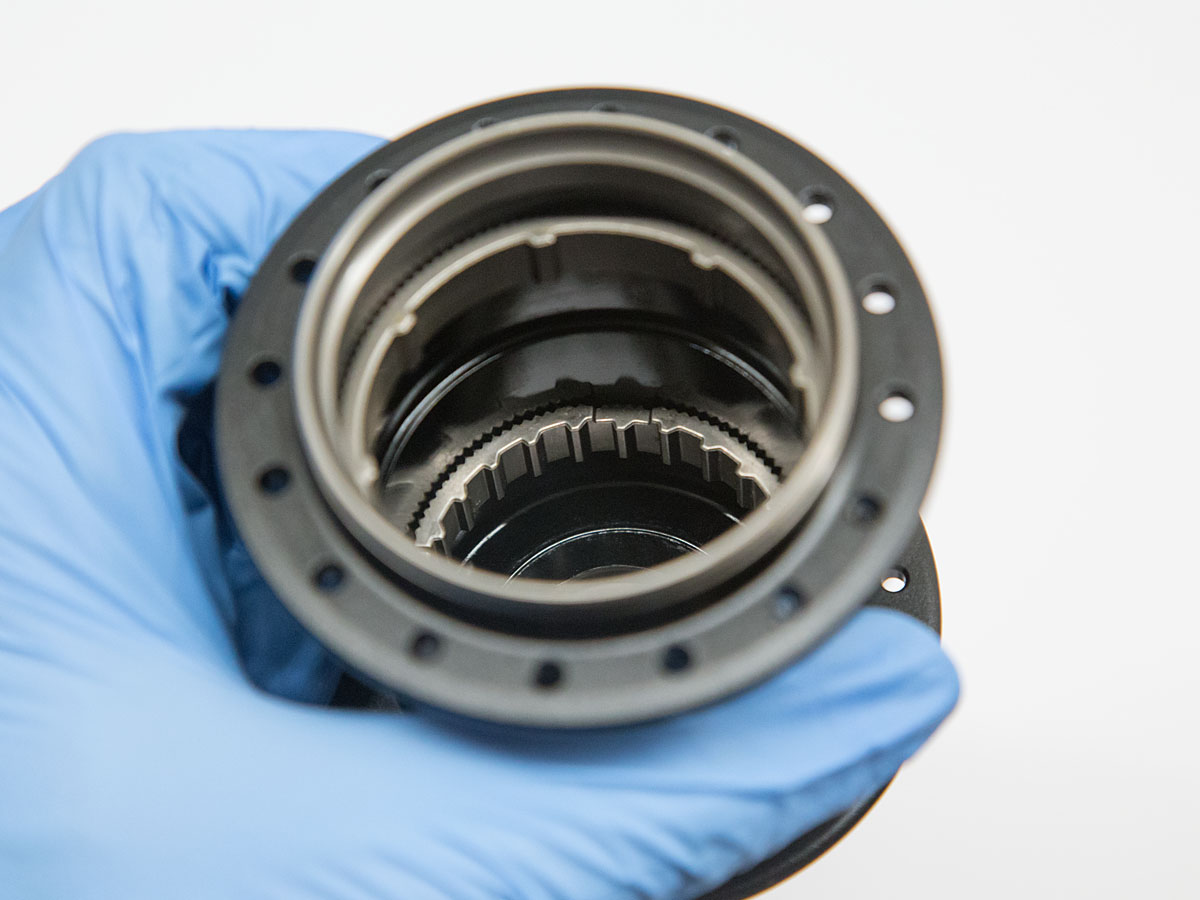

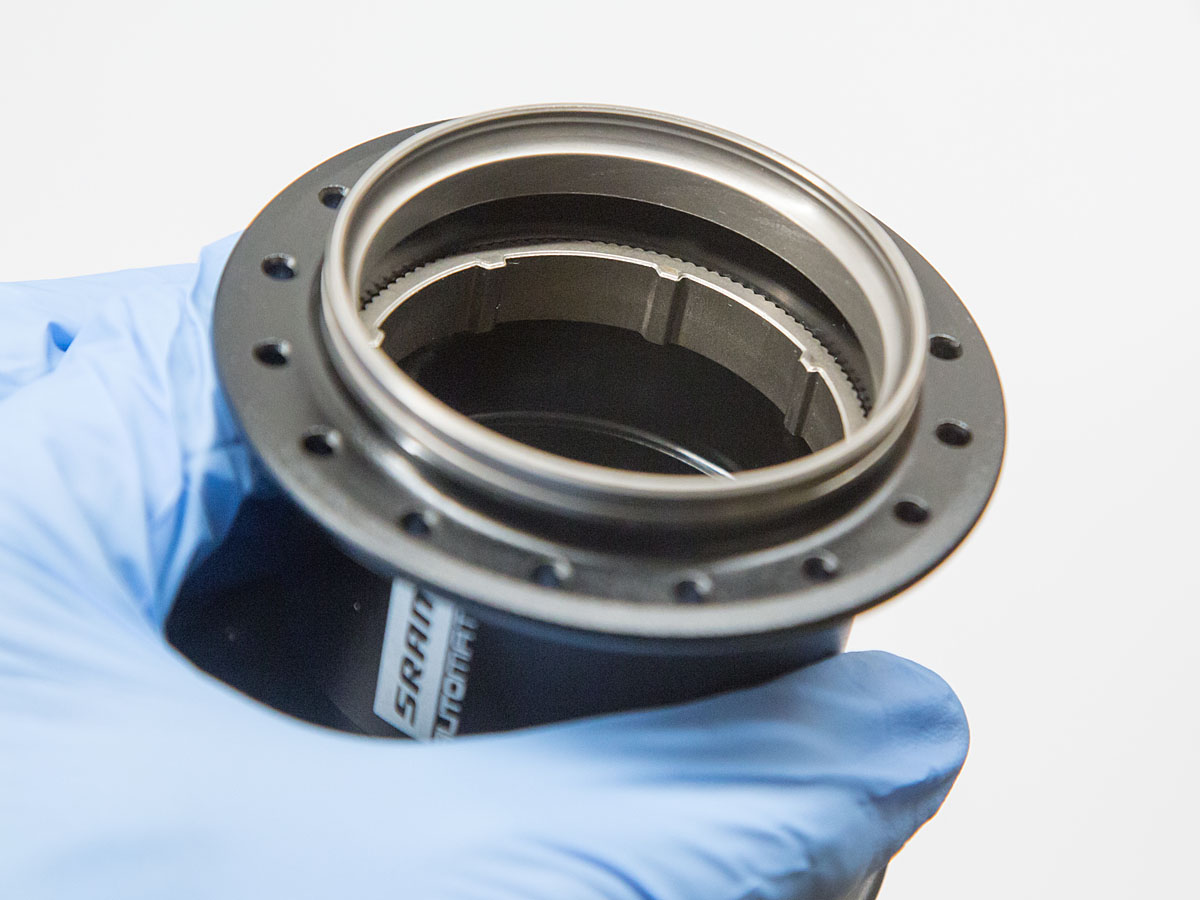

In comparison, the lighter 32H aluminium hub shell of the disc brake version of the hub has steel ring inserts pressed in where the pawls and dog ring engage, plus of course the bearing tracks:

Note that some NOS hubs have sticky/dried up grease on the ratchet teeth and pawls from the factory. This should be cleaned off and the pawls should only be lubricated with oil so they can move and click into place freely. These photos are after the cleanup.

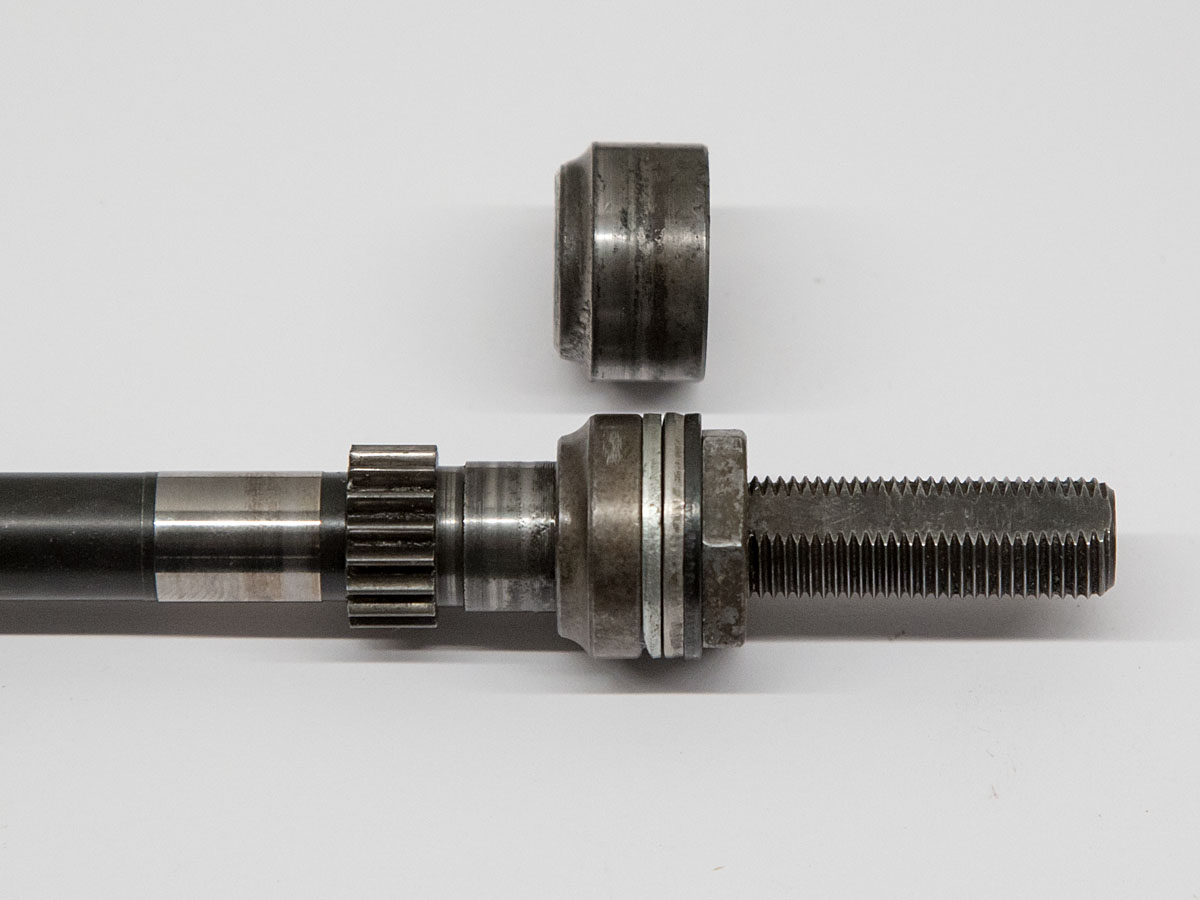

The O.L.D. of the aluminium shell / disc brake version of the Automatix hub is from the factory set up for 135 mm frames, but it can be reduced a bit by removing spacers between the fixed axle cone and right-hand locknut:

(In comparison, the coaster brake / freewheel versions of the hub have an over locknut dimension of 120 mm, expandable to 130 mm via included spacers)

The internal unit of the disc brake version and the Shimano roller brake version of the Automatix hubs has a slightly different mechanical design than the other:

Instead of a conventional radial drag spring like on the coaster/freewheel version, it has an axial friction spring mechanism comprised of a spring steel wave washer compressed between two metal discs. On the disc/roller brake hubs I have worked on so far, this wave washer mechanism had an unnecessary excessive amount of drag compared to the other version of the mechanism. It can be reduced to a more sensible amount of resistance by carefully flattening the wave washer by 1 mm and lightly greasing the contact surfaces.

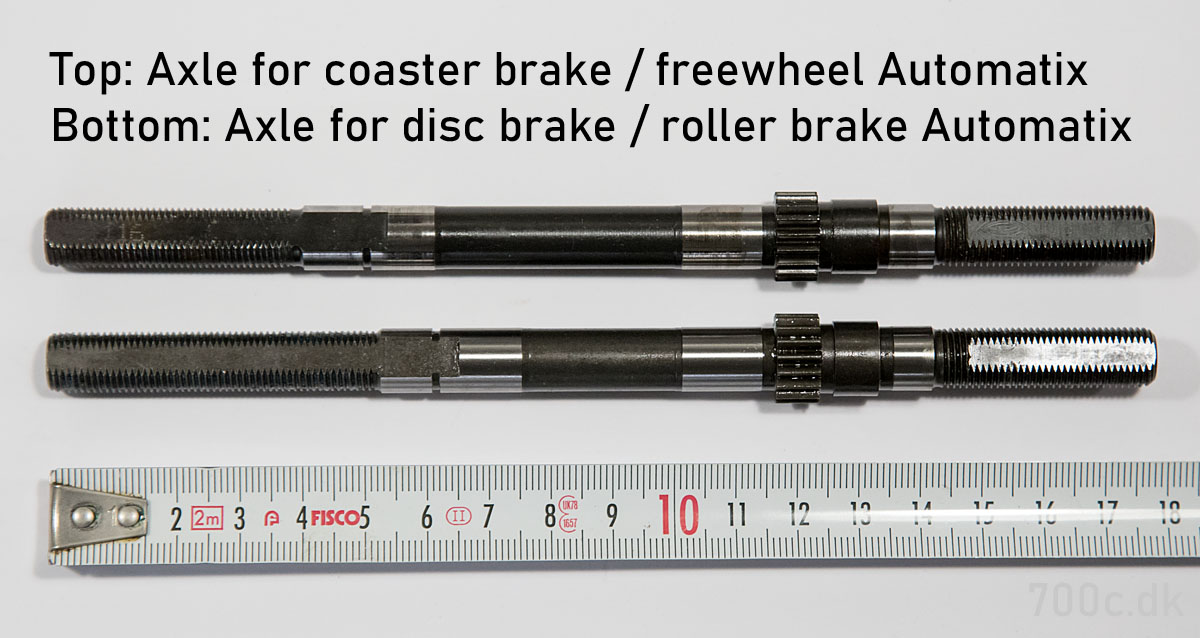

Also notice that the axles have some differences on the left side (location of the snap ring groove and contact surfaces) due to the different design of the pawl carrier and the left axle bearing cone:

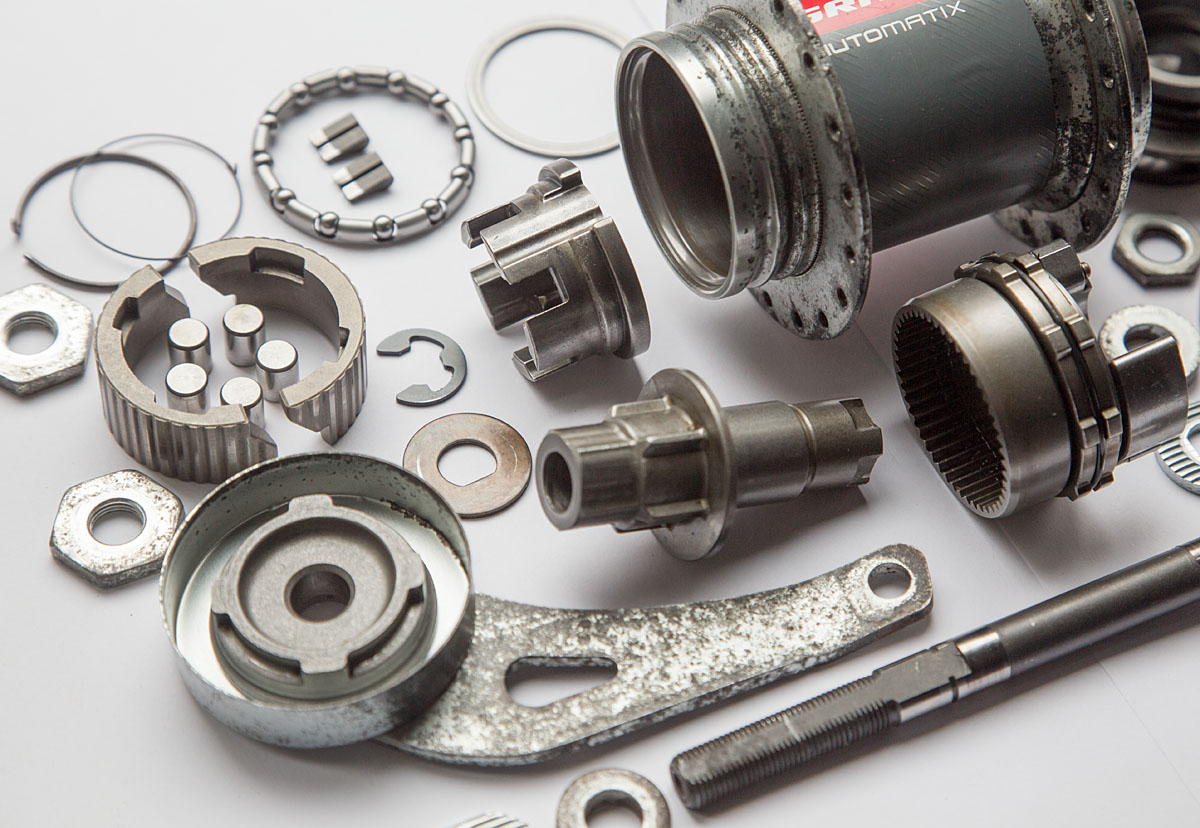

The heart of the Automatix (like the Automatic A2110) is the centrifugal clutch unit:

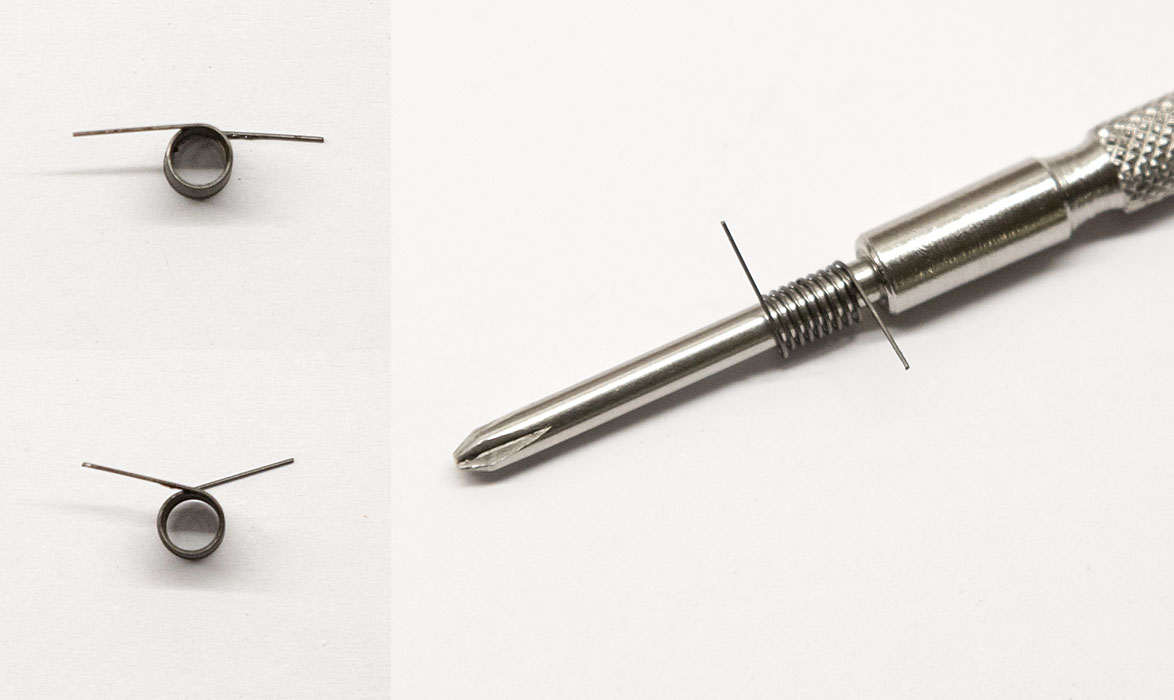

Two flyweights are mechanically linked to each other and held back by a tiny torsional spring. This spring controls the shifting point of the hub. The general consensus among bicycle enthusiasts who care about pedaling cadence is that the 36/32H versions of the hub shifts into second gear too early when used in a 622/700c/28" size wheel. The spring can be modified to change the rotational speed of which the hub shifts.

Since SRAM stopped production of internally geared hubs and related parts in 2017, there are no spare parts available for the hub, but some parts from earlier Sachs/SRAM models are compatible, like the planet gears, the left ball ring, the smaller driver ball ring, and the fixed bearing cone on the axle from three-speed hubs, like this one from a SRAM T3 (plus some spacers/washers to take up the difference in length):

Other spare parts like the larger right-side ball ring, dust cap, brake arm assembly, left-side drive pawls and most of the coaster brake components can also be taken from the contemporary SRAM i-Motion 3 hub.

Page last updated 2024-05-19 17:09. Some rights reserved (CC by 3.0)