Repairing and upgrading a hub driver bearing

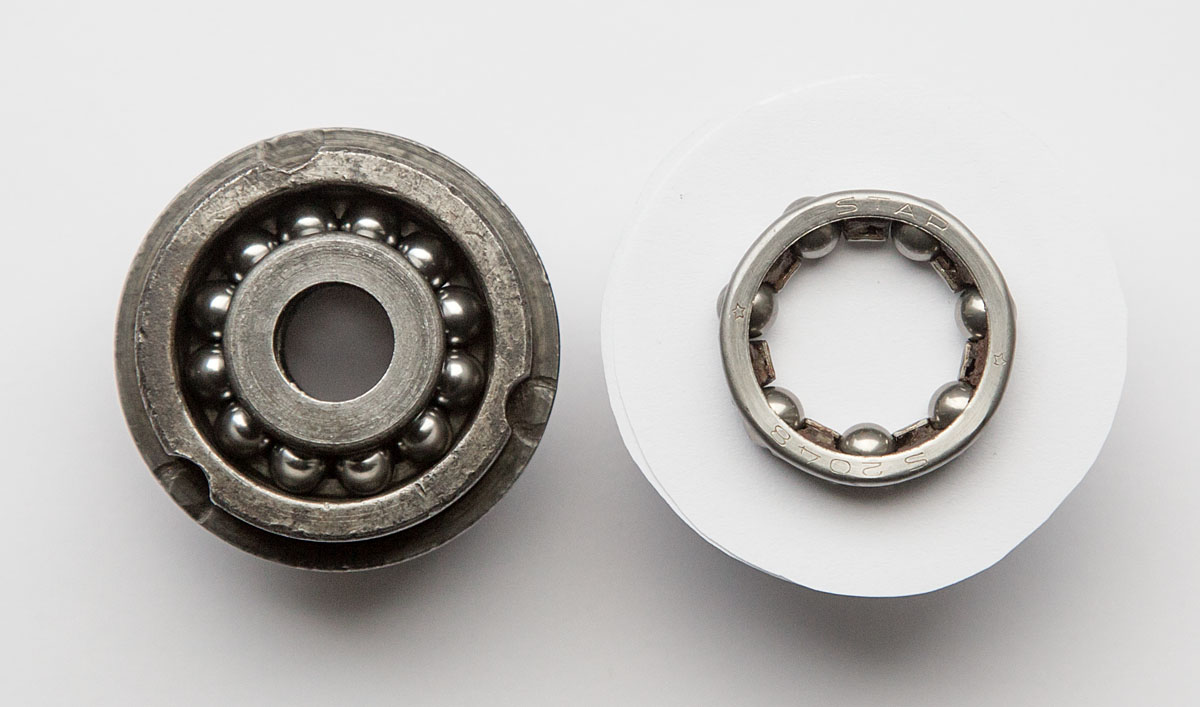

If a Sachs Torpedo Dreigang model H3111 / T3 or a Duomatic model 102 / R2110 has been ridden with insufficient lubrication, with bearings incorrectly adjusted, or has had grit entering the driver bearing of the hub, the ball retainer can fail:

The small ball bearing ring / retainer holds seven 7/32" (5.56mm) size balls. But the driver bearing cup can also be filled with a higher number of "loose" balls of the same diameter:

12 loose bearing balls will fit in a Duomatic driver instead of the original seven-ball retainer ring:

12 bearing balls will also fit in Sachs Dreigang model H3111 and SRAM T3 drivers, which share the same cup/cone bearing geometry as the Duomatics:

It might look like the balls are pinched up against each other, but there is actually sufficient room for the balls to roll freely:

The Sachs Pentasport, SRAM P5 and S7 have larger drivers and a slightly larger axle cone and will therefore take 13 7/32" balls:

The shape of the bearing tracks will retain the balls of a properly adjusted angular contact bearing without needing a retainer ring. You don't have to worry about balls falling out during use, you only need to be careful during assembly. This was also the way the original Torpedo Freilauf hub driver was set up for decades.

If you are repairing a Duomatic Model 102 with a damaged axle cone, spare parts can be difficult to find. But the axle cone for a Dreigang H3111 or SRAM T3 can also be used if a washer is placed on the back side to support the dust cap and provide the proper distance to the lock nut. The shape of the cone might look a little different, but the left side of the cone is recessed a bit, so the distance and shape of the actual bearing contact point is exactly the same on the two:

Profile comparison with spacer added:

An example of a Duomatic bearing repair with 12 loose balls and an axle fitted with a SRAM T3 axle cone (SRAM part number 00 0391 022 000). The extra spacer washer is not visible, but it is sitting under the axle dust shield. The photo was taken before the driver dust shield was pressed into the driver cup, to better show how the loose bearing balls are held into position with grease during assembly:

The switch to loose balls can be used as a repair when a spare part ball ring is unavailable, but it can also be considered an "upgrade" of the driver bearing, as more balls will distribute the load of the bearing on more contact points, making the bearing more resilient. Also, if the driver bearing track has some damage or pitting and a replacement driver cannot be found, more ball contact points will at least make the bearing run a little smoother, saving a hub that would otherwise not be in good enough shape to be used.

Page last updated 2024-04-18 22:12. Some rights reserved (CC by 3.0)